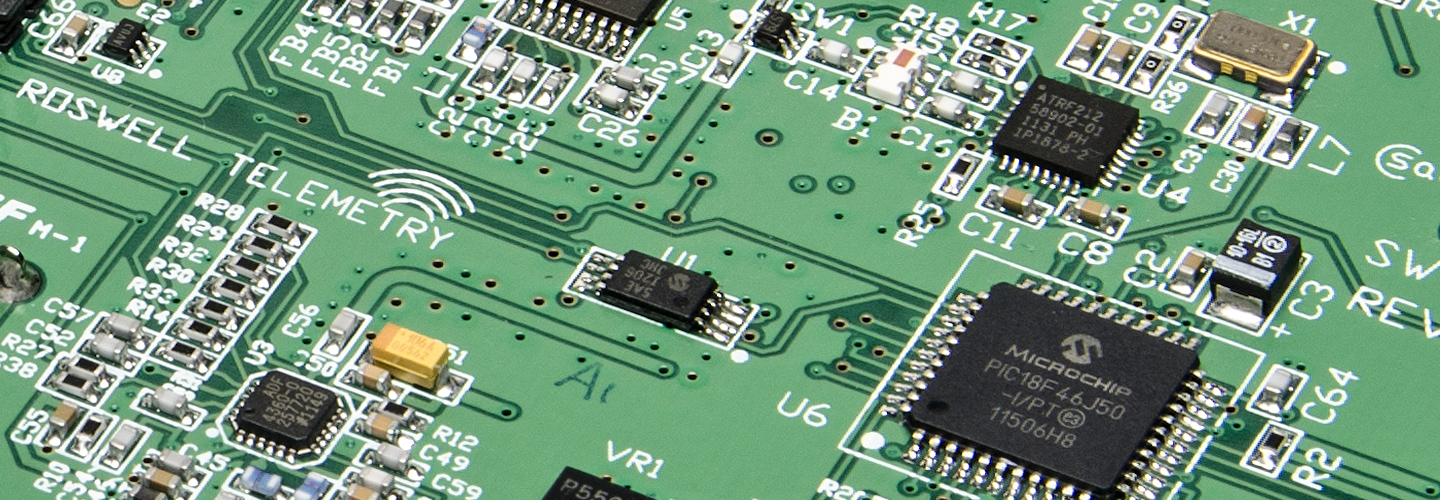

Expert printed circuit board assembly when premium quality is the only acceptable outcome

For high-mix, automated, prototype-to medium-volume printed circuit board assembly (PCBA assembly), SemiGen is your go-to, on-time provider. We help manufacturers of military electronics, commercial products, and medical instrumentation with their leadless, fine-pitch, BGA, and QFP assembly requirements. Our team of certified J-STD-001 and IPC 610 assemblers, combined with two, fully-automated, surface-mount MYDATA machines and high-temperature multi-zoned reflow ovens, are proficient in critical placements. We also offer additional robotic through-hole manufacturing capabilities to support your unique challenges. You can rest assured that whatever your requirements are, your boards will be delivered with the utmost quality and care.

SemiGen’s automated PCB assembly line can handle and place a full range of components on virtually any board. This includes everything from 01005 and CSP/FC components to complicated BGA and QFP types. With the trend towards miniaturization and odd-shaped components, it’s essential to have a partner with an all-in-one machine, and more importantly, the experienced staff to run it.

SMT Assembly Capabilities:

- High-mix automated PCBA

- Manual & Robotic through-hole

- Leadless

- Fine pitch

- VGA/BGA

- Micro BGA

- QFP

- LIDS

- In House Xray • Diverse passive components

- Large boards up to 44" x 32" and 1/2" thick

- Odd-shaped boards

- Intelligent Surface Impact Control (ISIC)

- Design services

- Quick-turn prototypes